Products Description

Mud Pump Spare Parts Rubber Piston;

BOMCO, HongHua, EMSCO, Gardner Denver, National, Oilwell, TSC, IDECO…

Support other customised sizes, Full-process in-house manufacturing.

Product Description:

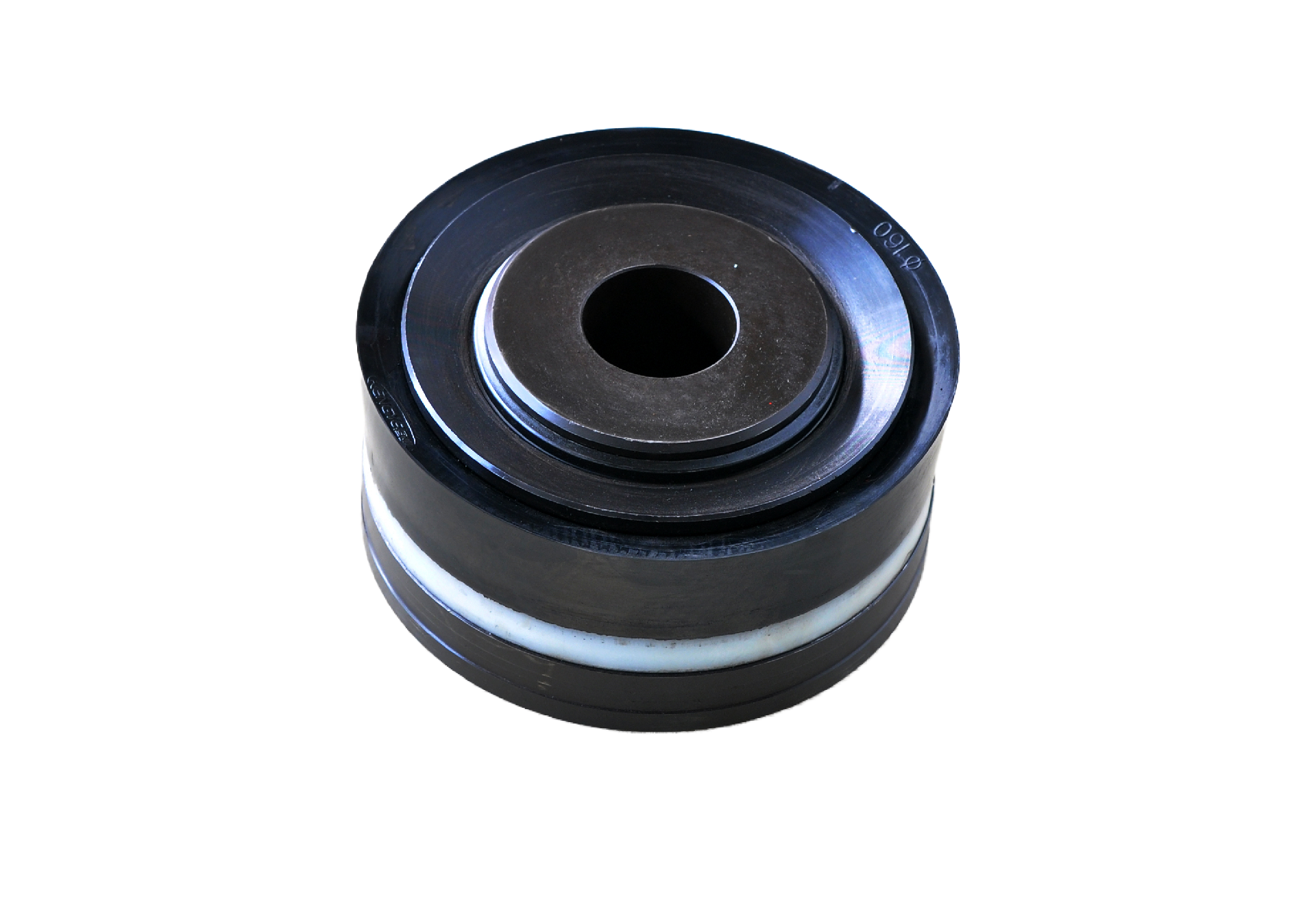

The piston produced by our company became a national invention patent product. (National invention patent certificate can be viewed)

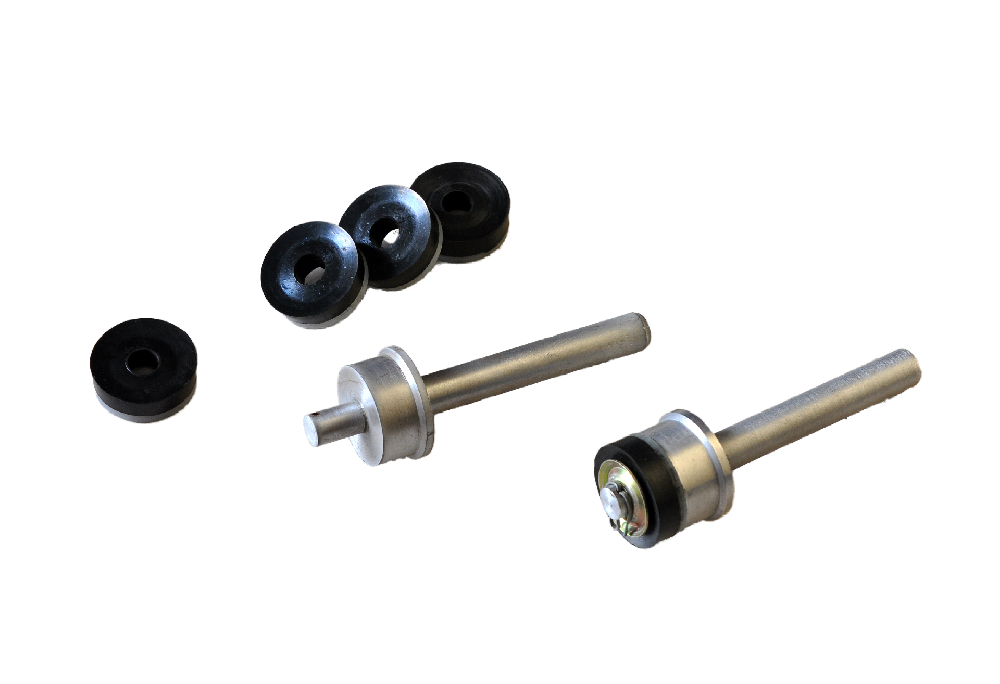

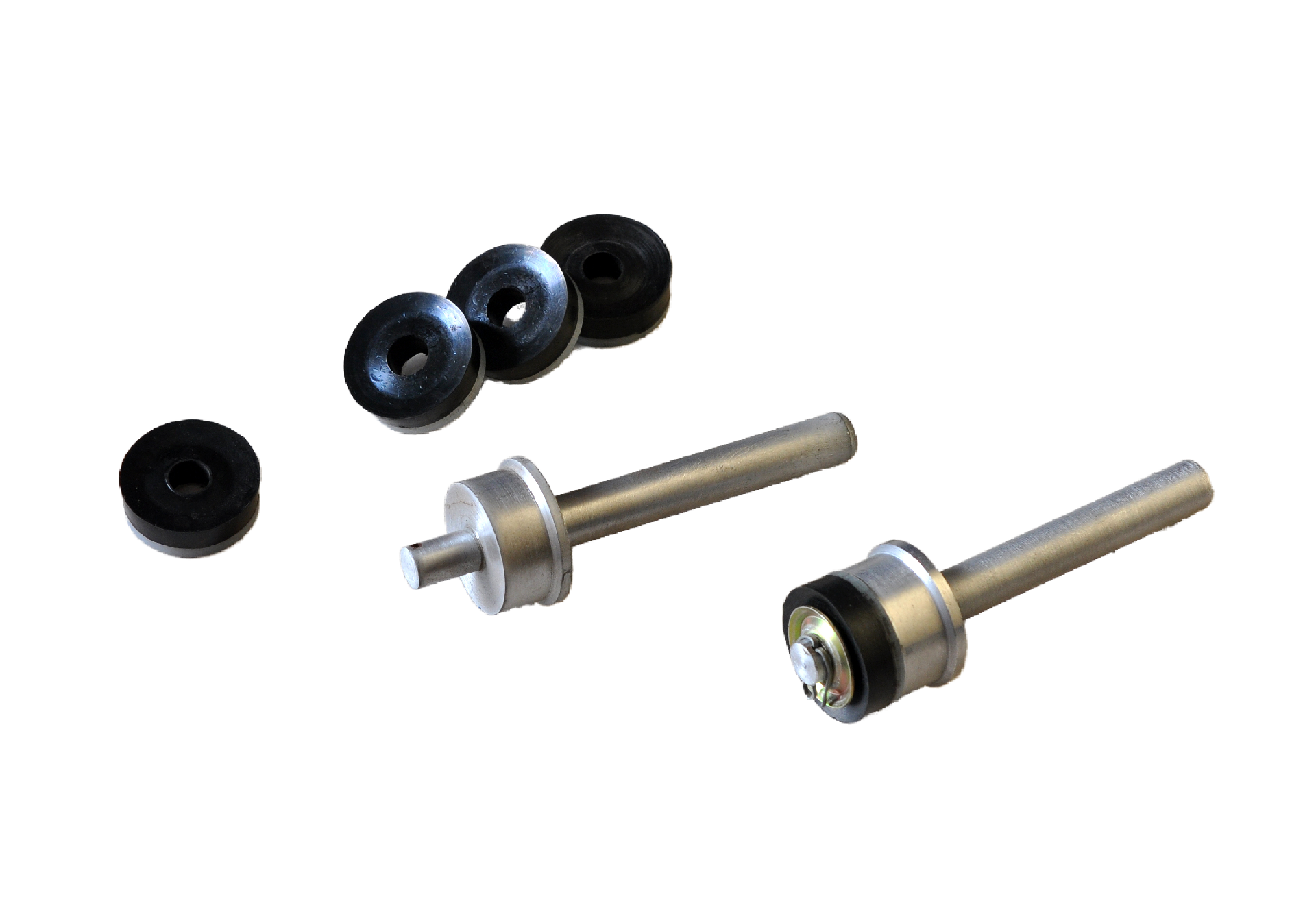

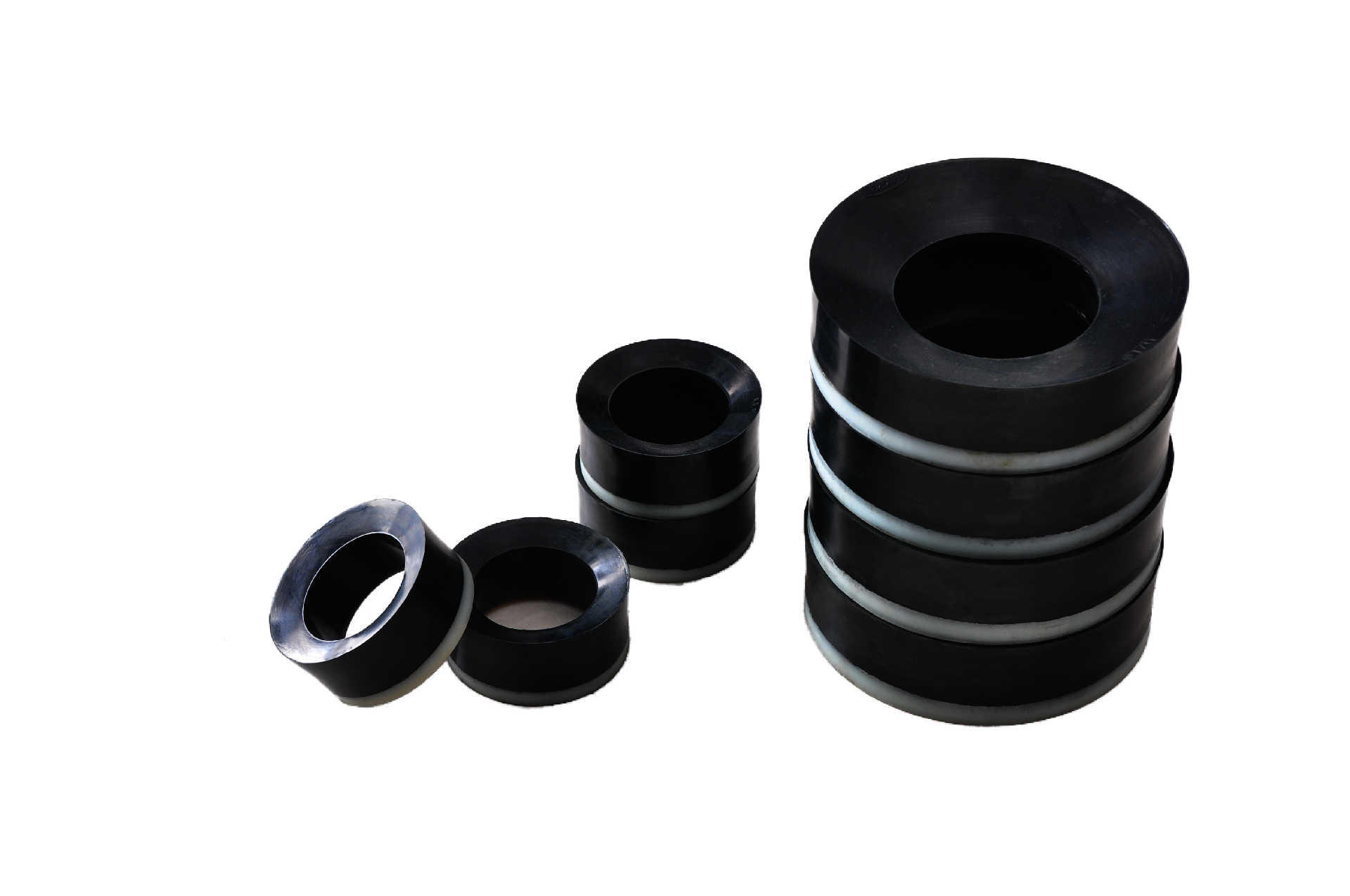

Including piston core, rubber skin, card spring, pressure plate and so on. The rubber skin is divided into high wear-resistant polyurethane material, butyl rubber and polyurethane plus high-performance woven fabric.

The product process adopts our company's patented technology, made the design adjustment structure, can be produced according to API standards are perfectly compatible with the use of the product.

Piston assembly is one of the main parts of mud pump hydraulic end system, drilling wear parts, mud pump exclusion pressure through the piston assembly reciprocating linear movement to achieve.

Product Features:

Patented technology structure

Extremely high tensile strength

Resistance to chemical corrosion

High wear resistance

Longer service life

Significantly reduce replacement and downtime costs

NBR rubber

Suitable for ordinary drilling working environment with working pressure below 20Mpa and working temperature not higher than 120℃. Excellent abrasion resistance, chemical corrosion resistance, long service life in ordinary drilling working environment.

Polyurethane rubber

Excellent resistance to oil, high pressure, corrosion and abrasion. Working temperature: -30℃-120℃. Suitable for oil-based mud with working pressure 34Mpa-38Mpa and working environment with high sand content.

HNBR Hydrogenated nitrile rubber

It is suitable for high temperature, high pressure, high corrosion working environment, working pressure 34-38Mpa, working temperature up to 150℃ above. Hydrogenated NBR is a kind of rubber used in aviation. Used in petroleum industry, hydrogenated nitrile rubber has abrasion resistance, oil resistance and chemical resistance, its amine resistance and steam resistance are good. Especially in high temperature and high pressure working environment, other rubbers are quickly destroyed under the action of hydrogen sulphide, carbon dioxide, methane, steam and acid, but hydrogenated NBR shows good comprehensive performance.

Product Specification Dimensions:

Φ100、Φ110、Φ120、Φ130、Φ140、Φ150、Φ160、Φ170、Φ180…

Support other customised sizes,Independent design and production of the whole process

Product Packaging:

Special cardboard box, product manuals, factory certification.

Q: Leather/cloth Surface Wrinkled, Uneven?

Remedy: pat the surface of the leather cloth with your hands and stretch on both sides

Q: Leather/cloth Surface Wrinkled, Uneven?

Remedy: pat the surface of the leather cloth with your hands and stretch on both sides

Q: Leather/cloth Surface Wrinkled, Uneven?

Remedy: pat the surface of the leather cloth with your hands and stretch on both sides

Why choose us?

- We pride ourselves on our attention to detail and commitment to quality, ensuring that every Driving Chains product we deliver meets the highest standards.

- Our Driving Chains products are designed with functionality and practicality in mind, ensuring they deliver maximum value to our customers.

- Our Driving Chains products are easily installed and maintained, providing our customers with a hassle-free experience.

- We are committed to providing our customers with accurate and transparent pricing on all of our Driving Chains products and services.

- We have a proven track record of delivering high-quality Driving Chains products and services to customers around the world.

- Our Driving Chains products are built to deliver exceptional results, providing our customers with a competitive edge in their industries.

- Our team of experienced professionals is dedicated to providing top-notch customer service, ensuring that every customer has a positive experience.

- We work closely with our customers to understand their unique needs and provide customized solutions that meet those needs.

- Our state-of-the-art production facility is equipped with the latest tools and equipment, allowing us to produce high-quality Driving Chains products efficiently and cost-effectively.

- We offer a wide range of customization options for our Driving Chains products, allowing customers to create their own unique designs.